Some things simply grow more lustrous with time.

GANZO delivers the world’s best finished leather products…

GANZO delivers the world’s best

finished leather products…

growing in esteem, day by day,

through long contact with your own hands.

As time passes and things are used for a long period, they age together with the personality of their owner and someday may even become a one-of-a-kind gem. We deem it appropriate to call such leather products “the world’s best.”

GANZO, the highest-quality line available anywhere, pursues the concept of “genuine” throughout the entire process, from the selection of materials, to cutting, skiving, stitching and polishing - without compromise. The persistence and energy of takumi (expert workmen) delivers products created by the hands of craftsman who are well-versed in Japanese culture and techniques.

The GANZO collection is an art form in and of itself - reaching the highest level of performance when chosen and used by you.

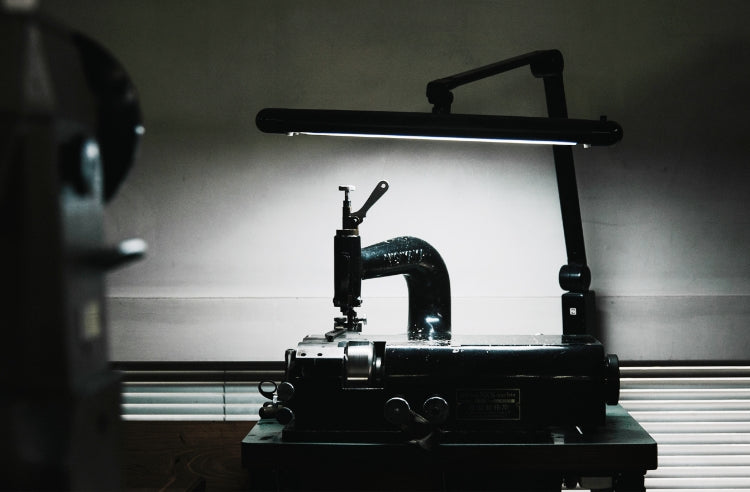

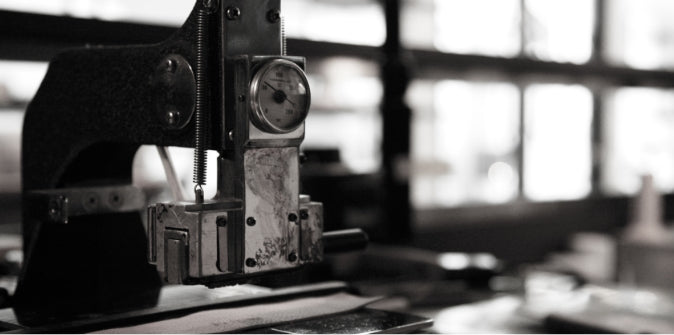

From design to inspection,

GANZO never compromises on quality.

Our artisans have passed on their unchanging passion for their work since our founding.

1

Each part is cut out using a pattern paper guide. We cut every piece individually - even the tiniest differences in cutting can ruin the beauty of the finished product.

2

The edges of the leather are colored to bring out the feel of the entire piece. Coating is applied twice using a proprietary Bordeaux color dye. Although this process appears simple, it is actually quite a difficult procedure.

3

A process called “creasing” is done around the edges of each piece. A heated iron is used to apply finely detailed lines to the leather. This purely ornamental procedure it gives rise to beautiful accents on the leather.

4

Once all of the parts have their edges polished and creased, they are assembled in the sewing process. Every aspect, from the location of individual stitches to their angle, are subject to GANZO’s strict proprietary methods.

5

The edges of the leather are lined with glue and folded inward in a process called “turning”. This process increases the strength of individual part. Delicate care is taken to avoid warping or bending of the material.

6

A cotton cloth is used to spread varnish on the leather edges in a process called “burnishing”. Soon after polishing begins, the edges quickly develop a brilliant shine. The same process also has a beveling effect, vastly improving the feel of the leather.

The cordovan leather used in this series has been treated with a laborious immersion-dyeing process and coated with an oil finish to give it a beautiful luster that stands out and contrasts with the Nume cowhide inside.

Wallet / Small Leather Goods

MORE

The cordovan leather used in this series has been treated with a laborious immersion-dyeing process and coated with an oil finish to give it a beautiful luster that stands out and contrasts with the Nume cowhide inside.

MORE

Showcasing the gentle glossiness and texture unique to shell cordovan leather, you will fully enjoy the varying color and luster of products in this series.

Wallet / Small Leather Goods

MORE

Showcasing the gentle glossiness and texture unique to shell cordovan leather, you will fully enjoy the varying color and luster of products in this series.

MORE

This series features a hybrid combination of bridle leather for the outside of the products and shoulder Nume leather for the inside.

Wallet / Bag / Small Leather Goods

MORE

This series features a hybrid combination of bridle leather for the outside of the products and shoulder Nume leather for the inside.

MORE

Guidi’s cowhide calf leather is unique for its translucent hue, depth of color, and uneven grain reminiscent of vintage items.

Wallet / Bag / Small Leather Goods

MORE

Guidi’s cowhide calf leather is unique for its translucent hue, depth of color, and uneven grain reminiscent of vintage items.

MOREGANZO flagship shop was launched from the desire to convey GANZO’s passion towards manufacturing and meticulous craftsmanship in closer proximity to our customers.

At GANZO flagship shop, alongside the extensive range of products from each series, we also set up a workshop within the store space, where we accept bespoke orders from our customers based on their personal preferences and requests.

5-2-7 Jingumae, Shibuya-ku, Tokyo, Japan 150-0001

3-3-7 Ginza, Chuo-ku, Tokyo, Japan 104-0061

Roppongi Hills Mori Tower 4F (WEST WALK 4F)

6-10-1 Roppongi, Minato-ku, Tokyo, Japan 106-6104

4-13-14 Minami Senba, Chuo-ku, Osaka-shi, Osaka Japan 542-0081

GANZO offers three distinct types of cordovan, each with its own unique charm. Here, we introduce the key characteristics of each series.

In Tuscany's Santa Croce, the workshop of ROCADO integrates these time-honored leatherworking methods, primarily used with cowhide, to craft fine cordovan leather.

Scratches and wrinkles that are left on articles over time become evidence of an enriched life.Let's take a look at three stories that depict the fascinating relationships between people and leather.